PRODUCTS CENTER

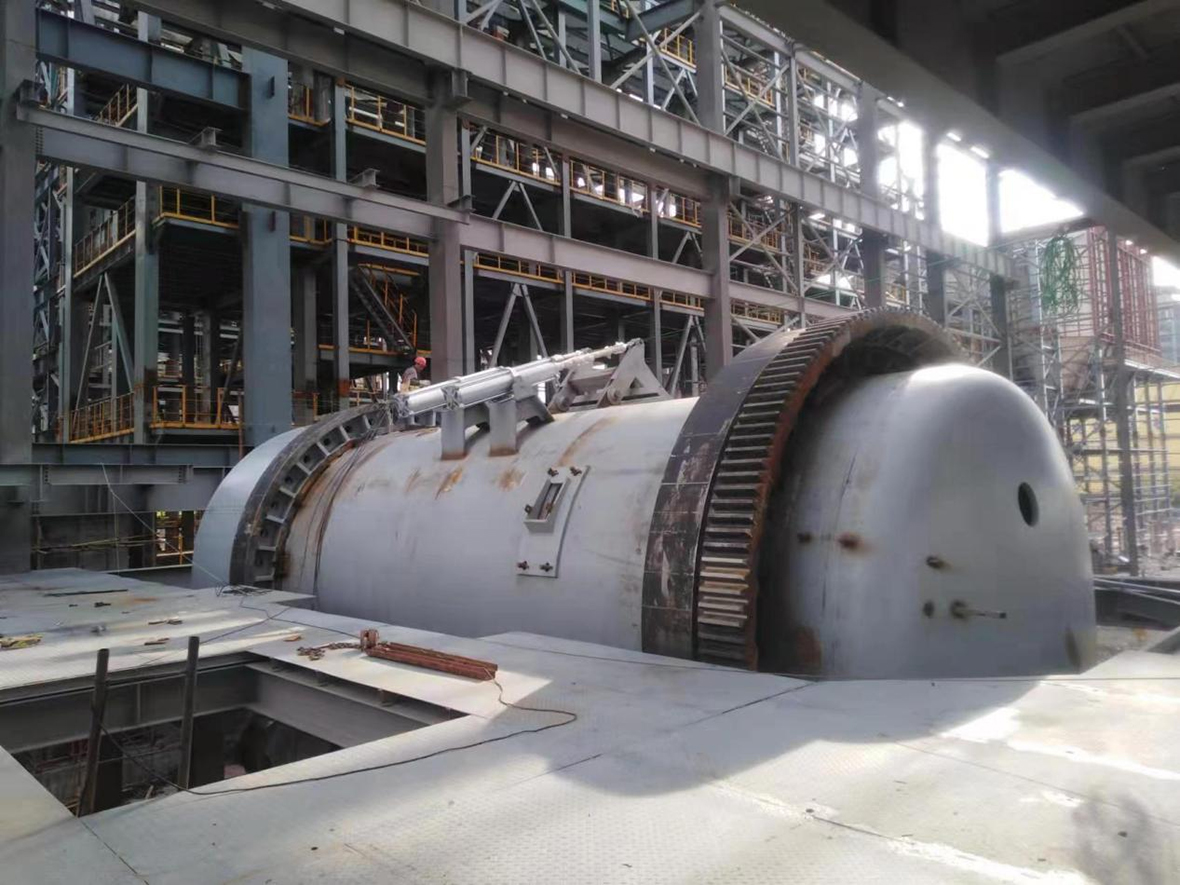

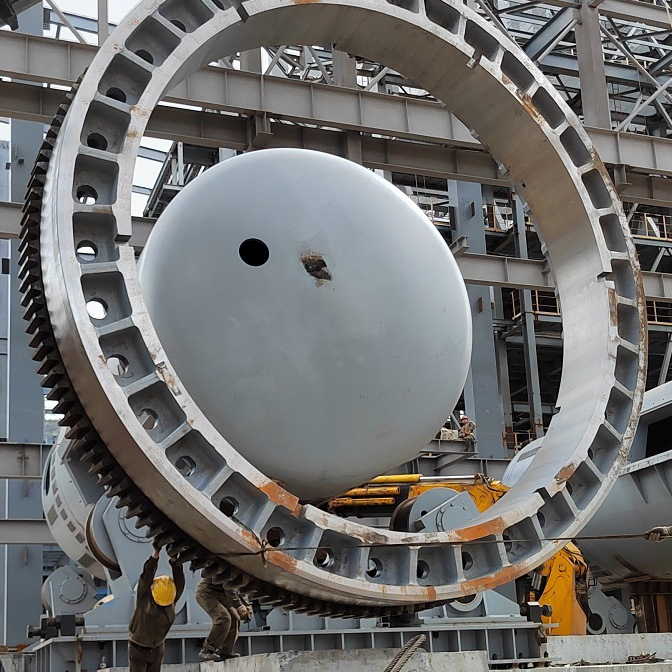

The rotary refining furnace is a cylindrical furnace body that can rotate 360°. The furnace body is equipped with 2-4 air ducts, a furnace mouth and a copper discharge port. When the furnace body is rotated, the air ports can be buried under the liquid surface to perform oxidation and reduction operations. There is a furnace mouth on the cylindrical furnace body, which is used for charging and tapping copper. The furnace mouth is equipped with a furnace lid. The furnace lid is only opened during charging and copper tapping. The melting period, oxidation period and reduction period are all covered. of. There are a small number of tuyere openings on the side of the furnace body, through which high-pressure air is introduced during the oxidation period and reducing agent is introduced during the reduction period. When the tuyere is not in operation, it should be placed above the melt surface. When performing redox operations, tilt the furnace so that the tuyere is buried in the melt. The rotary refining furnace requires external heating, so it is equipped with a fuel burning device and a smoke exhaust port.

Structure:

The rotary refining furnace is a cylindrical furnace body that can rotate 360°. The furnace body is equipped with 2-4 air ducts, a furnace mouth and a copper discharge port. When the furnace body is rotated, the air ports can be buried under the liquid surface to perform oxidation and reduction operations. There is a furnace mouth on the cylindrical furnace body, which is used for charging and tapping copper. The furnace mouth is equipped with a furnace lid. The furnace lid is only opened during charging and copper tapping. The melting period, oxidation period and reduction period are all covered. of. There are a small number of tuyere openings on the side of the furnace body, through which high-pressure air is introduced during the oxidation period and reducing agent is introduced during the reduction period. When the tuyere is not in operation, it should be placed above the melt surface. When performing redox operations, tilt the furnace so that the tuyere is buried in the melt. The rotary refining furnace requires external heating, so it is equipped with a fuel burning device and a smoke exhaust port.

Features:

(1) The structure of the furnace body is easy to operate, mechanization, high level automatic, cancling the manual operation such as the Air duct insertion, slag removal,copper feeding.

(2) The furnace has large processing capacity, good technical and economic indicators, and high labor productivity.

(3) Reduce the consumption of air duct material,reduce the cost of the producing

(4) The furnace has good airtightness. The use of negative pressure operation improves the environment and improves working conditions. It also reduces heat radiation loss. The furnace body dissipates less heat and reduces fuel consumption.

The main problems of the rotary refining furnace are that it is difficult to process large pieces of miscellaneous copper materials due to its deep molten pool, small heating surface, and slow material melting, and the primary investment is high. Therefore, it is rarely used in recycled copper plants.

Features:

The liquid blister copper discharged from the continuous converting furnace is put into the rotary anode furnace for refining and returned to the furnace.

The anode-rotating furnace has the advantages of high production efficiency, high degree of mechanization, and easy operation.

In addition, it also has the following new features:

(1)Spray compressed air and reducing agent into the molten pool through a special redox tuyere device.

To carry out oxidation and reduction operations, the independent tuyere brick structure design also improves the tuyere extended refractory life and easy replacement.

Using Breathable bricks technology. Nitrogen gas is introduced into the furnace through the breathable brick device, so that The melt is always in a slightly stirred state and the temperature field is uniform, which greatly shortens the oxidation reduction time. At the same time improving the quality of anode copper.

Using lean oxygen combustion technology. Dilute oxygen combustion technology is a technology that has emerged in recent years.

Energy-saving combustion technology, the temperature of the oxygen combustion furnace is high and uniform, the amount of flue gas is greatly reduced, and the

The amplitude improves the thermal efficiency of combustion, thus significantly reducing fuel consumption.

The upper part of the furnace tail is used to discharge smoke, which can increase the effective volume of the furnace. solved

The eccentric flue on the end wall has the disadvantage of being easy to bond and difficult to seal. There is a special design at the flue mouth water-cooled sealed hood.