NEWS&EVENTS

Home > News&Events > Company news > Tower Type Smelting Furnace: Revolutionizing Industrial Melting Efficiency

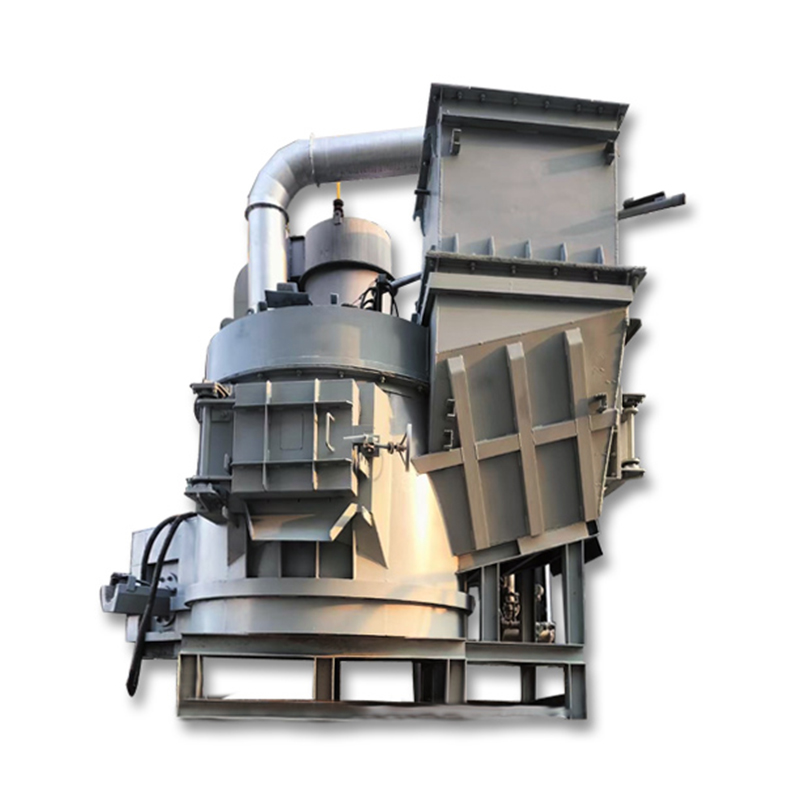

Tower Type Smelting Furnace: Revolutionizing Industrial Melting Efficiency

In the realm of industrial melting technology, the tower smelting furnace stands out as a pioneering innovation that combines advanced engineering with unparalleled efficiency. As a leading manufacturer of industrial smelting furnaces, our company takes pride in introducing this cutting-edge equipment, designed to meet the ever-growing demands of the metals and materials processing industries. This article delves into the functionalities, advantages, and promising application prospects of the tower smelting furnace.

Functionalities of the Tower Smelting Furnace

The tower smelting furnace is engineered to optimize the melting process through its unique vertical design. Unlike traditional horizontal furnaces, the tower configuration allows for better heat distribution and material flow. The furnace is equipped with high-performance burners or electric heaters, depending on the specific requirements, ensuring rapid and uniform heating of the charge materials.

One of the key functional features of the tower smelting furnace is its advanced control system. This system enables precise temperature regulation, crucial for achieving the desired alloy composition and minimizing energy consumption. Additionally, the furnace is designed with efficient exhaust systems to remove impurities and fumes, enhancing the overall quality of the melted metal.

Advantages of the Tower Smelting Furnace

Space Efficiency: The vertical design of the tower smelting furnace significantly reduces the footprint required, making it an ideal choice for facilities with limited space.

Energy Savings: The furnace's superior insulation and efficient heating mechanisms contribute to reduced energy consumption. This not only lowers operational costs but also aligns with global sustainability goals.

Enhanced Product Quality: The uniform heating and effective impurity removal capabilities of the tower smelting furnace result in higher-quality melted metal, with consistent alloy composition and reduced porosity.

Operational Flexibility: The furnace can be tailored to accommodate a wide range of materials, from ferrous to non-ferrous metals, and can be easily integrated into existing production lines.

Maintenance Convenience: The vertical design facilitates easy access for maintenance and cleaning, reducing downtime and extending the equipment's lifespan.

Application Prospects of the Tower Smelting Furnace

The tower smelting furnace holds immense potential across various industries, particularly in the metals processing sector. In the automotive industry, where high-quality alloys are essential for manufacturing durable and lightweight components, the furnace's precision and efficiency offer a significant advantage.

In the aerospace sector, the ability to produce high-purity metals with consistent properties is critical. The tower smelting furnace's advanced control system and impurity removal capabilities make it an ideal choice for this demanding industry.

Furthermore, the furnace's space-saving design and energy efficiency make it an attractive option for small to medium-sized enterprises (SMEs) looking to upgrade their melting capabilities without a substantial increase in operational costs.

As the global focus on sustainability intensifies, the tower smelting furnace's energy-saving features position it as a future-oriented solution. Its ability to reduce energy consumption and minimize waste aligns with the principles of green manufacturing, making it a preferred choice for environmentally conscious businesses.

In conclusion, the tower smelting furnace represents a leap forward in industrial melting technology. Its innovative design, combined with advanced functionalities and numerous advantages, opens up new horizons for metals and materials processing industries. As we continue to push the boundaries of innovation, the tower smelting furnace stands at the forefront, ready to revolutionize the way metals are melted and processed. For more information or to discuss your specific requirements, please contact us. We are committed to providing tailored solutions that meet your unique needs and drive your business forward.