NEWS&EVENTS

Home > News&Events > Company news > Lead Ore Induction Smelting Rotary Furnace: Innovation of Efficient Smelting Technology

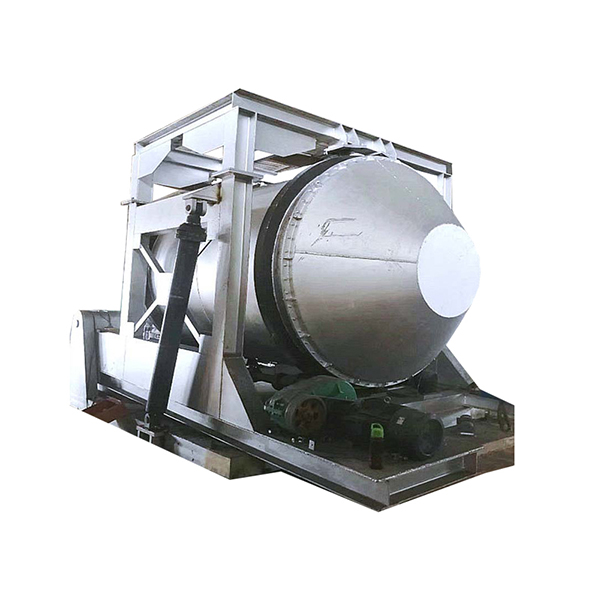

The lead ore induction smelting rotary furnace is an important equipment in the modern lead smelting industry. It combines the high efficiency of induction heating with the flexibility of the rotary furnace, providing an advanced and environmentally friendly solution for the smelting of lead ore.

The working principle of the lead ore induction smelting rotary furnace is based on the principle of electromagnetic induction heating. When an alternating current passes through the inductor, an alternating magnetic field is generated around the inductor, which generates eddy currents inside the lead ore, thereby rapidly heating the lead ore to a molten state. At the same time, the design of the rotary furnace enables the furnace body to rotate slowly, so that the lead ore in the furnace can be evenly heated, avoiding local overheating or unmelted phenomena. This design not only improves the smelting efficiency, but also ensures the full reaction and refining of the lead ore.

In terms of structure, the lead ore induction smelting rotary furnace is usually composed of a furnace body, an induction heating system, a transmission mechanism, a sealing device and a control system. As the main part, the furnace body is made of refractory materials and can withstand various stresses during high-temperature smelting. The induction heating system is responsible for providing the heat energy required for smelting, and its efficiency and stability are directly related to the success or failure of the smelting process. The transmission mechanism ensures that the furnace body rotates at an appropriate speed, while the sealing device prevents the leakage of heat and harmful gases, protecting the working environment and the safety of operators. The control system is responsible for monitoring and adjusting various parameters in the furnace to ensure the stability of the smelting process.

The advantages of the lead ore induction smelting rotary furnace are its high efficiency, energy saving and environmental protection. Due to the rapid and uniform induction heating, the lead ore can reach the melting temperature in a shorter time, thereby improving production efficiency. At the same time, the design of the rotary furnace makes more efficient use of fuel heat and reduces energy consumption. In addition, advanced flue gas treatment systems and waste heat recovery technologies further reduce the emission of harmful gases and energy waste, which meets the requirements of sustainable development.

However, there are also some challenges in the lead ore induction smelting rotary furnace, such as high equipment prices and high requirements for operation and maintenance technology. Therefore, when selecting and using it, it is necessary to comprehensively consider factors such as production needs, cost budget and technical level.

In general, the lead ore induction smelting rotary furnace plays an increasingly important role in the lead smelting industry with its high efficiency, energy saving and environmental protection. With the continuous advancement of technology and the increasing requirements for environmental protection, the application prospects of lead ore induction smelting rotary furnace will be broader.