NEWS&EVENTS

Home > News&Events > Company news > How to use crucible furnace to recycle silver from waste photo paper and waste film

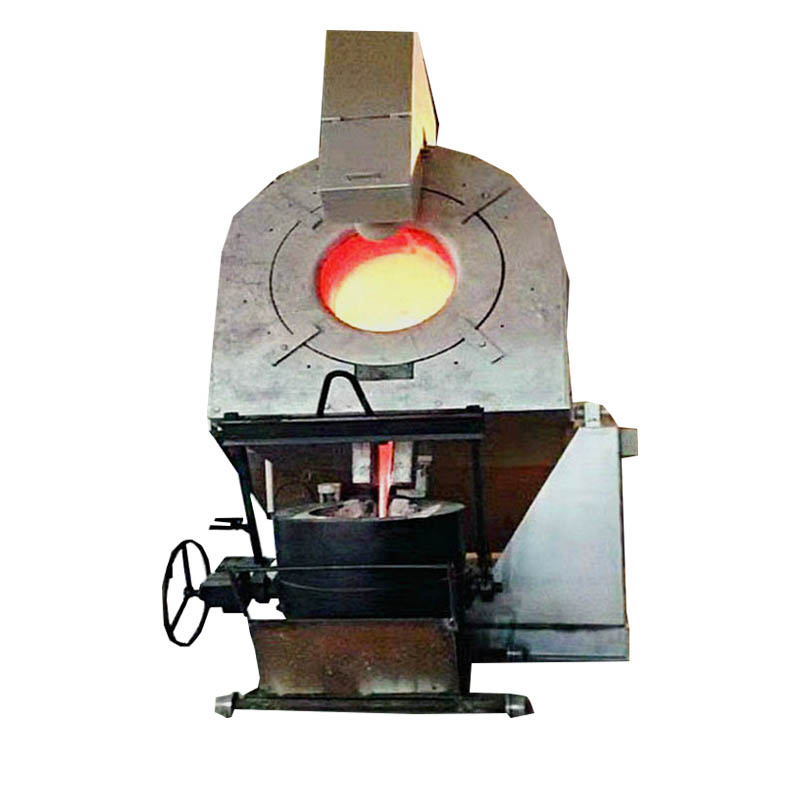

Silver is an important precious metal and is widely used in various aspects of production and life. At present, in addition to researching silver substitutes and advocating the conservation of silver, it has become very urgent to recycle silver as a secondary resource. Crucible furnace is the main furnace for smelting and recycling silver.

Photo paper contains 2~6g/m2 of silver, film 3.5~8g/m2, and X-ray film is double-coated and contains more silver. In the process of photography and filmmaking, part of the silver on the photo paper or film remains on the photo or negative, and part enters the fixing solution. Silver used for photosensitive materials accounts for almost all of the silver used, and the fee is also high, so it is important to recycle silver from this type of waste.

The silver content of photo paper is 2-6g/m2, film is 3.5-8g/m2, and X-ray film is double-coated, with a higher silver content. During photography and film making, part of the silver on the photographic paper or film remains on the photo or negative, and part flows into the fixing solution. Therefore, it is also important to extract silver from this waste.

The discarded photographic paper or film is concentrated in the incinerator and ignited, so that the film base and the latex layer become ash, and the silver is dispersed in the ash powder. If sodium carbonate (Na2CO3) and borax (Na2B4O7•10H2O) are directly added to the ash powder, it is placed in a graphite crucible for high-temperature melting, and the residue is removed to obtain silver. Although this process is simple, the amount of silver in the residue is large and there is a large loss. The preferred process is: add 8-10% dilute nitric acid in a beaker, dissolve the silver into silver nitrate, filter out the residue, and then add 3 mol•L¯’ dilute hydrochloric acid until all the silver forms silver chloride.

After sedimentation, filtration, washing, and obtaining clean silver chloride, select the following steps to recover silver. After drying AgCl, add enough NazCO3 (twice the theoretical amount), place it in a graphite crucible, cover it with borax and glass powder, and melt it at 1100℃. After the reaction is completed, remove the scum, pour the molten silver liquid into the mold, and take out the mold after cooling to obtain a silver ingot.

With the increasing types and quantities of mining waste (liquid), the comprehensive recovery and utilization of secondary silver resources has become particularly important, and crucible furnace smelting silver will play a vital role.