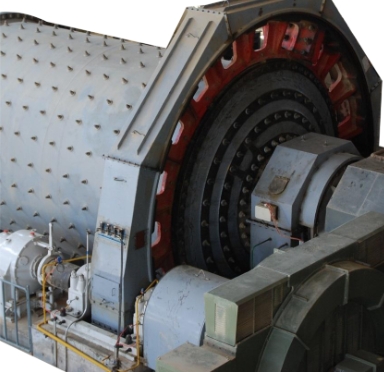

Ball mill is an important equipment for crushing raw materials and then grinding them. Ball mill is an industrial equipment suitable for cement, silicate products, new building materials, refractory materials, fertilizers, non-ferrous metal smelting, glass and ceramics, etc. It is suitable for dry or wet grinding of various minerals and other easy-to-grind materials.

When the ball mill rotates, due to the friction between the liner on the inner wall of the cylinder and the influence of centrifugal force, the grinding body rotates with the cylinder, rises to a certain height, and then falls freely under the influence of gravity, hits the bottom material and breaks it. In addition, the grinding body will slide and roll when rotating, so there will be friction between the grinding body, liner and material, so that the material is ground very finely. Because new materials are continuously added to the feeder, there is a material surface difference between the materials at the feed port and the discharge port, which can force the flow of materials. At the same time, when the abrasive falls, its impact on the material will produce an axial thrust. At the same time, the air flow in the mill also helps the flow of materials. Therefore, even if the cylinder of the mill is placed horizontally, the material can slowly flow from the feed port to the discharge port, thus completing the work of the powder.

During the rotation of the cylinder, the grinding body in the cylinder has three basic forms:

1) When the speed is too low, the grinding body and the material are driven by the roller to a position equal to the friction angle due to friction, that is, the "pouring state", which has a grinding effect on the material, but the impact effect on the material is poor, and the grinding effect is poor.

2) When the speed is too high, the grinding body and the material are affected by the centrifugal force of the tube and rotate with it. This is the so-called "turnover state", and the grinding body will not have an impact or crushing effect on the material;

3) At an appropriate speed, when the grinding body is lifted to a certain height, it is thrown down, that is, the "throwing state", at this time, the grinding body has a greater impact and grinding effect on the material, so that it has a higher crushing effect.

Reasonable ball mill working speed, required power, production capacity and calculation of ball mill mechanism all require the determination of a suitable motion state.