NEWS&EVENTS

Home > News&Events > Company news > Controllable temperature reverberatory furnace for smelting lead ore

Lead smelting refers to the process of extracting lead and its compounds from ore, including the reduction of lead oxide to metallic lead and the extraction of metallic lead from lead salt. Temperature is an important parameter in the lead smelting process. Stable control of it is of great significance to improving production efficiency and reducing energy consumption. The reverberatory furnace with adjustable smelting temperature is of great significance to lead smelting.

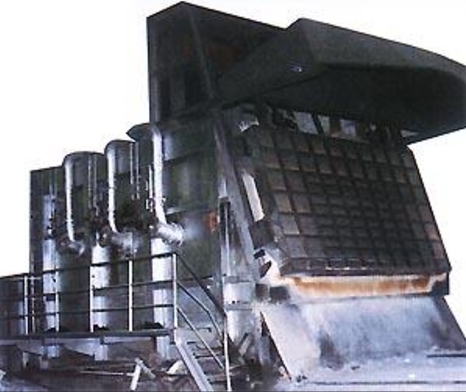

The reverberatory furnace with adjustable lead ore smelting temperature consists of a combustion chamber and a smelting chamber in a single space, characterized in that the combustion chamber is located above the smelting chamber, with a flue on the upper part and a slag pit below, and a slag hole is opened at the tail of the combustion chamber; the coal powder injector, the pulverizer, the conveyor belt and the mill are connected to the front end of the combustion chamber in sequence; a temperature control device is provided in the upper center of the combustion chamber for controlling the temperature.

At present, the solid fuel of the general reverberatory furnace is layered combustion, requiring the operator to stir the solid fuel constantly to make it fully burned. The reverberatory furnace has low thermal efficiency, high power consumption, and serious environmental pollution problems. In addition, during the smelting process, the important parameter of temperature cannot be accurately controlled. Most temperature-controlled lead ore smelting reverberatory furnaces use solid fuel as a heating source. The furnace structure mainly consists of two parts, one is a relatively independent combustion chamber, and the other is a smelting chamber. It not only has high thermal efficiency, low coal consumption, and less pollution, but also can accurately control the smelting temperature.

In the lead smelting process, temperature control is one of the key links. The appropriate temperature can ensure the melting and extraction efficiency of lead, while also reducing energy consumption and reducing damage to equipment. By accurately controlling the temperature of the reverberatory furnace, the purity and output of lead can be optimized and production efficiency can be improved.

In the lead smelting process, temperature control is an important step. The appropriate temperature can ensure the smelting and extraction of lead, and can reduce energy consumption and damage to equipment. By accurately controlling the temperature of the reverberatory furnace, the purity and output of lead can be optimized and production efficiency can be improved.