The raw materials for lead smelting are mainly lead sulfide concentrate and a small amount of lump ore. There are two methods for smelting lead: pyrometallurgy and hydrometallurgy. Pyrometallurgy basically uses sintering roasting-blast furnace smelting process, accounting for 85-90% of the total lead production; followed by reaction smelting method, its equipment can be hearth furnace, short kiln, electric furnace or rotary furnace; precipitation smelting is rarely used.

Introduction to the process flow of lead-zinc ore dressing:

1. Crushing: First, crush the large stones with a crusher.

2. Ball milling: The crushed stones are ball milled with a ball mill.

3. Mud washing: send the 20-200 mesh fine powder material into the classifier for separation and sorting to select the mud and sand:

4. Mixing: send the material after sorting and removing the mud and sand into the mixing barrel, add reagents and stir it fully;

5. Concentration: flotation operation is carried out in the flotation machine, and wet concentrate is obtained after 1 roughing, 5 concentrating, 2 sweeping, and qualified concentrate is obtained by controlling the pulp concentration, pH, and adding different reagents;

6. Dehydration: wet concentrate is concentrated, filtered and dehydrated;

7. Drying: the dehydrated lead and zinc concentrate is dried to facilitate transportation and storage.

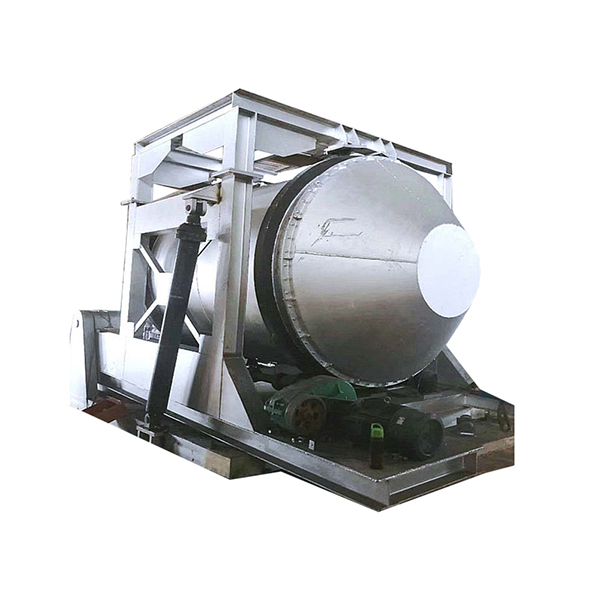

For the extremely difficult to sort lead-zinc oxide mixed ore, a unique treatment method has been formed in my country after long-term research, that is, the lead-zinc oxide mixed ore or its enriched product is sintered or agglomerated and melted in a blast furnace to obtain crude lead and molten slag containing lead and zinc. The slag is further smoked in rotary furnace.