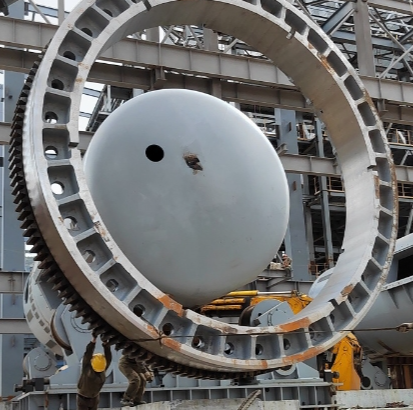

The rotary anode furnace is a fire refining furnace type compared with the fixed anode furnace type. It has the same process principle as the reverberatory furnace type, but has great differences in structure and operation mode. Its advantages are:

(1) Suitable for working in a comfortable working environment. Because it is fully enclosed, black smoke will basically not be emitted during reduction. Even during reduction, weak negative pressure operation can be used to suck a large amount of black smoke into the chimney, reducing pollution to the bottom layer. The rotary anode furnace is deeply loved by the majority of employees because it does not require manual intubation or manual slag removal.

(2) When copper is discharged, the rotation of the furnace body can be adjusted to keep the copper discharge amount and copper pulling speed consistent. In the electrolytic aluminum electrolysis process, especially in the automatic production line.

(3) The biggest advantage of the rotary anode heating furnace is its large rated power, so it can achieve high production capacity and good economic benefits.

(4) Using natural gas as a reducing agent can not only improve resource utilization, but also protect the environment. Through the unique redox sealing device, compressed air and reducing agent are sequentially injected into the molten pool. Redox operation is carried out. The nozzle area adopts an independent damper structure, which prolongs the service life of the material and facilitates replacement.

(5) The permeable brick technology is adopted, and nitrogen is introduced into the furnace through the permeable brick device, so that the material is in a micro-stirring state, and the temperature field is evenly distributed, which can greatly shorten the redox time and improve the quality of anode copper.

(6) Oxygen-enriched combustion, as an emerging energy-saving combustion method, has the advantages of high temperature, uniformity, and low emissions. It can greatly improve the thermal efficiency of the boiler and greatly reduce fuel consumption.

The rotary anode furnace is a new type of smelting furnace that adapts to the modern large-scale production pattern. It is large in scale and has a high degree of mechanization and automation. It can fully utilize its advantages and effectively control its disadvantages to achieve good economic benefits.