The rotary furnace is a furnace with a long history that was transformed from a reverberatory furnace. There are cupola rotary furnaces and gas-fired iron-melting rotary furnaces.

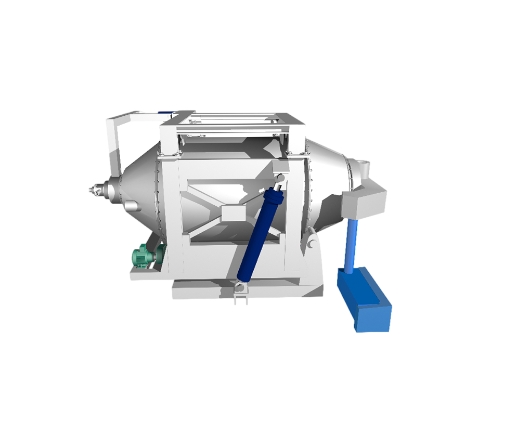

The body of the rotary furnace is generally composed of an exhaust cone section, a middle section, a lining, and a burner hole cone section. In general, the diameter of the exhaust port is larger than the diameter of the burner port. Therefore, the filling equipment is generally installed at the exhaust port, and the feed enters through the exhaust port. In order to facilitate the inspection of new linings or the removal of old linings, the three parts of the exhaust cone section, the middle section, and the burner hole cone section are generally connected as one by flanges.

A regenerative ironmaking furnace, a feeding system, a burner water system, an oxygen station, a gas supply system, a combustion controller, fixed and movable smoke pipes, etc. Its gas supply method is a liquefied natural gas station, which consists of a workshop crane, a bucket, a loading and unloading platform, a hydraulic slide, etc. The feeding mode has high requirements on the height of the building; if the net height of the plant does not meet the requirements, a scraper or scraper is required. If there is already pipeline natural gas in the local area, there is no need to build a new liquefied natural gas receiving station.

As a pure oxygen recovery blast furnace gas reflux furnace, it has a history of more than 50 years abroad and is particularly suitable for my country's small and medium-sized foundries. my country is a developing country with a vast territory, a wide range of industries, and extremely unbalanced development. Most small and medium-sized foundries are mainly labor-intensive industries, playing an irreplaceable role in absorbing local labor and maintaining social stability. At present, most of my country's small and medium-sized foundries have cancelled the coking iron cupola and switched to electric furnace smelting, which has brought about a significant increase in carbon dioxide emissions and production costs.

It can be seen that the gas-fired iron smelting rotary furnace has developed rapidly and has become the main iron smelting equipment.