NEWS&EVENTS

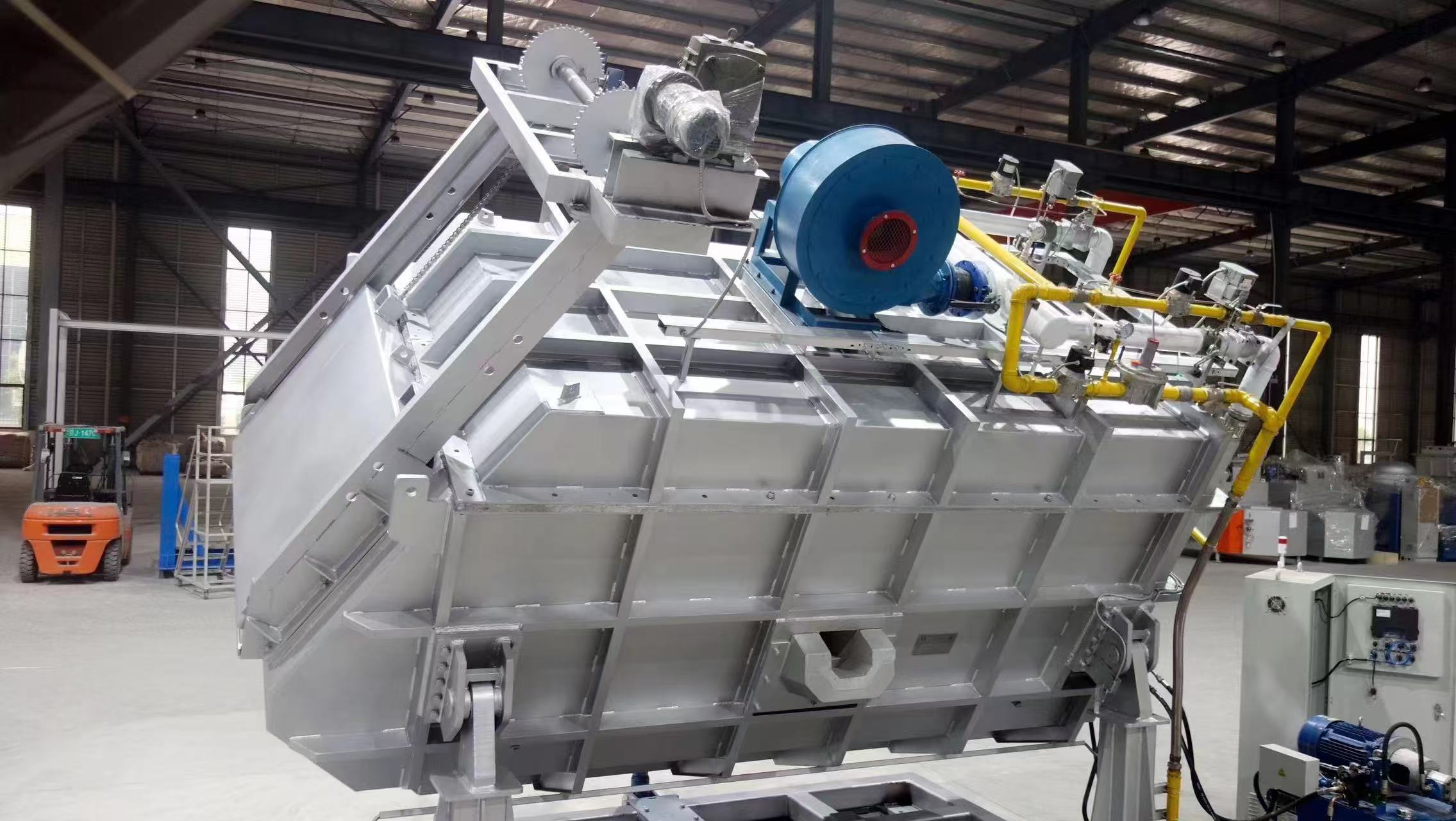

The tilting furnace type is based on the reverberatory furnace and the rotary furnace, and is an optimized design after absorbing the advantages of the two furnace types. The furnace type is relatively complex. The tilting furnace belongs to the scrap copper refining furnace type. Due to the complexity of the incoming materials and the generally high impurity content, it is very easy to form adhesion in the furnace during production, and the adhesion cannot be quickly melted and removed, resulting in the deterioration of the furnace hearth adhesion, affecting the effective use volume of the furnace hearth.

The production operation of the tilting furnace has an obvious operation cycle. The natural gas flow rate is different at different periods in the production process of a single furnace, resulting in frequent changes in the heat load in the furnace. Due to the particularity of the tilting furnace operation, the surface of the water jacket cannot be slag-covered, and the fire-facing surface of the copper water jacket is in direct contact with the flue gas. In the absence of slag protection, the water jacket expands violently due to heat. This type of furnace has very high requirements on the cooling strength and casting quality of the copper water jacket of the furnace body, especially the water jacket on the top of the furnace door. In addition to processing electrolytic residual electrodes, the tilting furnace also contains a certain amount of scrap copper in its input materials. The scrap copper has a high impurity content, which makes it very easy for the furnace bottom to stick during the production process of the tilting furnace. The main formation area of the tilting furnace bottom sticking starts from the low-temperature areas of the furnace, such as the combustion end wall, the smoke exhaust end wall, and the root of the side wall of the oxidation-reduction zone, and gradually expands to form a ship-shaped furnace bottom, which ultimately leads to a reduction in the effective volume of the furnace.

Therefore, the technical transformation of the tilting furnace is of great significance. It can improve the service life of the water jacket on the top of the furnace door, simplify the internal buried pipeline of the water jacket, reduce the difficulty of casting the water jacket, reduce the flow resistance of the cooling circulating water, and greatly enhance the cooling strength of the water jacket. It can greatly improve the service life of the water jacket. It can also improve the technical transformation of the furnace mouth water jacket structure and the masonry structure of the redox port that restrict the production of the tilting furnace to improve their service life.