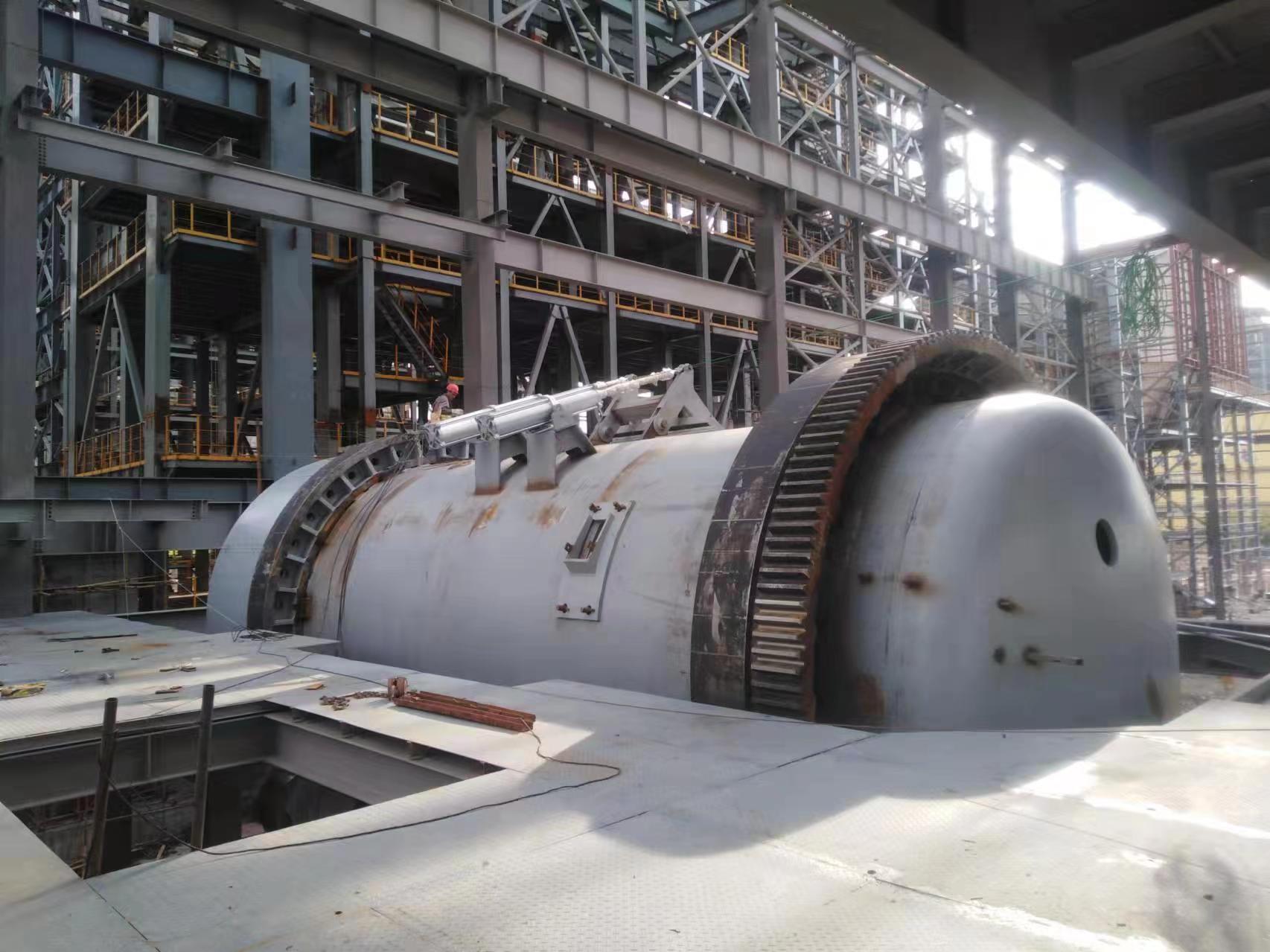

Roller ring: The roller ring of the rotary anode copper melting furnace is made of 15 cast steel. The roller ring is fixed by wedge-shaped fixation. During installation, the verticality between the end face of the roller ring and the axis of the furnace body is adjusted with a wedge block, and the outer circle of the roller ring and the furnace body are positioned with a stopper and welded to the outer shell of the furnace body, and then the wedge block is tightened with a hammer of a certain weight. After the wedge block is positioned, it is spot welded with the furnace shell. After the gear pair is adjusted and installed, one end of the wedge block is welded to the furnace shell. This method of fixing with a wedge block is convenient for installation and adjustment. It can also increase the rigidity of the furnace shell and reduce the deformation of the shell. Since the gap between the wedge blocks increases the heat dissipation area of the roller ring, the load of the furnace is transmitted to the roller ring through the wedge block. The roller ring does not directly contact the furnace shell, avoiding wear on the shell. Judging from the equipment manufacturing, installation and use, it has a simple structure and is easy to manufacture and install.

In the supporting device of the rotary anode copper melting furnace, the rotating shaft structure is made of 35 cast steel. In order to reduce the load borne by each supporting wheel, thereby reducing the structural size of the supporting wheel, two sets of multiple supporting wheels are used, and the bearings used are rolling bearings. This is because the operation of the rotary refining furnace is different from that of the blowing converter. The converter has a large impact when adding block materials and cleaning slag at the furnace mouth, and usually uses sliding bearings; while the rotary refining furnace operates relatively smoothly, so a rolling bearing structure is used, which has low resistance and is easy to maintain. The left and right bearing seats of the supporting wheel are integral castings and machined at one time. The coaxiality of the two bearing holes can be guaranteed. The bottom structure of the bearing seat is a hollow shaft, which is supported on another sliding bearing seat. Therefore, the supporting wheel can swing freely, but its swing amount is small, so the sliding bearing seat has no bearing bushing and lubricating oil groove. The base of the sliding bearing seat is a steel plate welded structure. Compared with the cast iron base, the former is light in weight and easy to manufacture.