NEWS&EVENTS

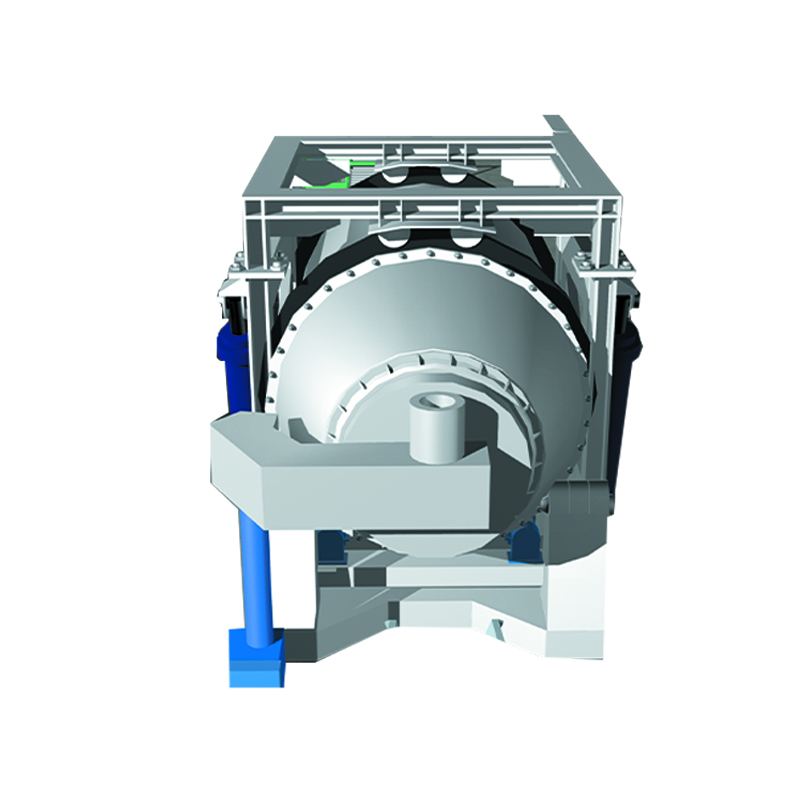

Furnace structure and burner performance of rotary iron furnace. The lining materials and lining thickness included in the furnace structure have a certain impact on fuel consumption.

If the heat storage coefficient of the furnace lining material is large and the furnace lining thickness is too large, the furnace lining will inevitably consume more fuel. The furnace body diameter, furnace body length, etc. included in the furnace body structure have a great impact on fuel consumption through the matching between the burner performance and the furnace body parameters. A more common situation is that the length of the furnace body is short and the flame length of the burner is long. The two are poorly matched. A large amount of heat generated by combustion enters the chimney, and the fuel consumption required for melting and overheating of the rotary furnace will be greatly increased. ; In a rotary furnace with a serious mismatch between the burner and the furnace body, the temperature in the furnace is very low and pig iron cannot even be melted. The ideal situation for the combustion performance of the burner to match the parameters of the furnace body is: within the entire heating power range of the burner, at least at the maximum power point of the burner, the highest temperature point generated by combustion in front of the burner basically coincides with the center of the furnace. At this time, the exhaust gas escaping from the exhaust hole carries the least amount of heat.

Heating system. The so-called heating system refers to the control relationship between the heating power of the rotary furnace and the melting stage. The basic rules for heating power control of rotary furnaces are: when the charge begins to preheat, the lowest heating power is used; as the furnace temperature rises, the heating power gradually increases; during the period of overheating of the molten iron, the maximum heating power is used.

Heats melted per day. The fuel consumption of a pure oxygen gas regenerative iron furnace is related to the number of melting furnaces per day. Generally, the fuel consumption of the second furnace is about 10% lower than that of the first furnace, and the third furnace is 5% lower than the second furnace.