NEWS&EVENTS

To analyze the advantages of pure oxygen gas-fired iron melting rotary furnaces, you must first understand that there are several ways to melt iron, and then you can compare their advantages and disadvantages in terms of cost, environmental protection, comprehensive economic and technical indicators, etc.

At present, there are five ways to melt cast iron: ① single melting in coke-burning cupola; this melting method is generally limited to the production of low-grade castings; ② duplex coke-burning cupola and induction furnace; ③ single melting in induction furnace; ④ gas cupola and induction furnace Duplex; ⑤ Single melting of pure oxygen gas rotary furnace. The following is a brief comparative analysis of the cost, environmental protection, production flexibility, melting characteristics and other aspects of the above five melting methods.

This article will start with a comparison in terms of cost. The cost of melting cast iron in a pure oxygen gas regenerative iron furnace is generally lower than that of an electric furnace, but always higher than that of a coke-burning cupola. The fuel consumed for melting 1 ton of metal charge is shown in the table below.

Comparison of melting costs among five melting methods

Melting methods coke Coke-burning cupola induction pure oxygen gas Gas-burning cupola

and cost items cupola + induction electric furnace electric furnace rotary furnace + induction electric furnace Double

Double

Amount of fuel and other materials consumed per ton of metal charge

Coke/kg 135 125 0 0 0

Electricity/kwh 0 45 600 0 45

Natural gas/m³ 0 0 0 50 60

Oxygen/m³ 0 0 0 130 15

Ceramic balls/kg 0 0 0 0 10

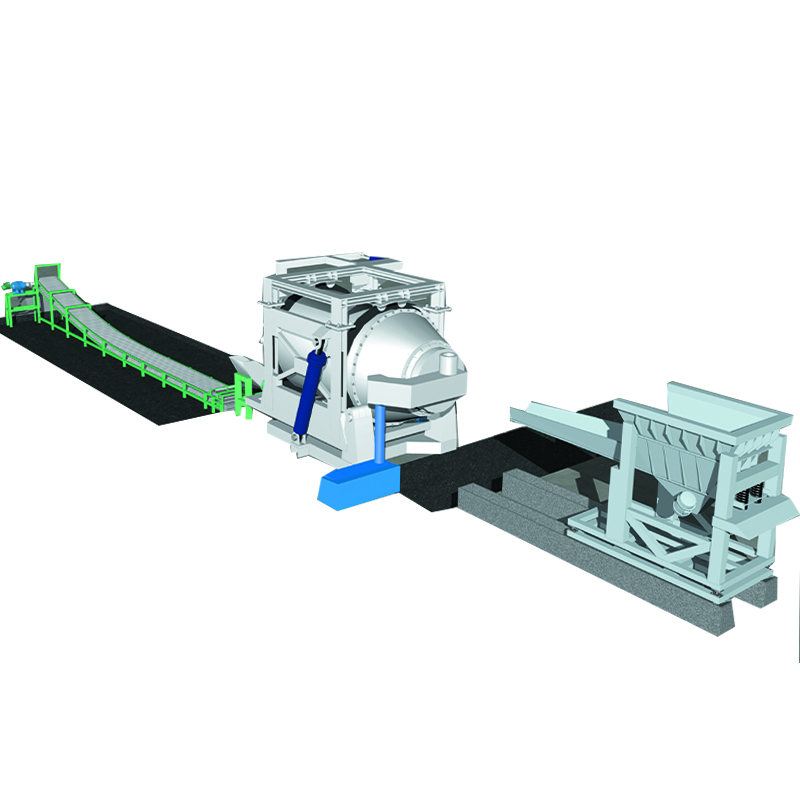

pure oxygen gas-fired iron melting rotary furnace has a history of nearly 100 years in developed countries. The furnace is the most friendly cast iron melting equipment in the environment today. The investment cost and production cost are lower than the inductive electric furnace. It is a strong competitor of an inductive electric furnace. It is a new choice in the reconstruction or reconstruction of small and medium -sized cast iron plants and cast iron workshops.